3D vita pirinty vita pirinty titanium alloy dia mivoaka

Metal Additive Manufacturing (MAM) is revolutionizing production methods in many industries, especially in the aerospace, automotive, and biomedical fields. However, there are still many technical problems with the further widespread adoption of MAM. One of the main obstacles is the control of the grain structure.

Poor control of the grain structure will affect its thermal cracking properties and lead to anisotropic mechanical properties, especially in high-performance alloys. The alloys currently used in the industry were originally designed for conventional production processes, and were not optimized for MAM processes. New alloys with high strength and best solidification properties are needed to maximize MAM absorption as a competitive manufacturing approach for high-performance components.

For decades, people have realized that small and equiaxed grains can reduce the tendency of hot cracking and improve its performance, for example, through Hall-Petch relationship enhancement. However, in MAM, due to the extremely high cooling rate and the unbalanced solidification of the thermal gradient, the main feature of the crystal grains is a columnar and textured microstructure. Therefore, the formation of equiaxed grains in MAM is a huge challenge. Although progress has been made in obtaining fine equiaxed grains by adding grain refiners to the MAM of aluminum alloys, there is still no commercial refiner that can effectively refine the microstructure of titanium grains.

Under the leadership of Professor Mark Easton from the Additive Manufacturing Center of the Royal Melbourne Institute of Technology (RMIT) and the team of Professor Hamish L. Fraser from Ohio State University (co-corresponding author), Dr. Dong Qiu and Dr. Duyao Zhang collaborated with the Commonwealth Scientific and Industrial Research Organization (CSIRO). ), the University of Queensland and the University of Nevada collaborated to design tunable microstructures for MAM components (especially light alloys).

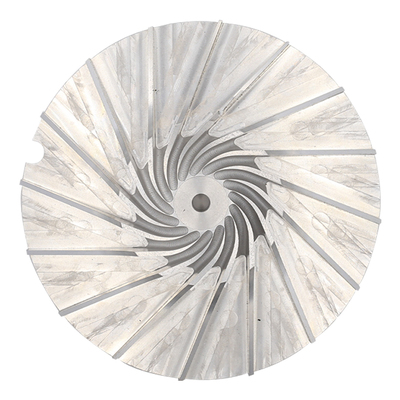

The theory behind this project is based on the interdependence theory proposed by Professor David StJohn and others (Acta Mater. 2011, 59, 4907). This kind of titanium-copper alloy has a high microstructure supercooling ability, which is due to the distribution of alloying elements during the solidification process, and it can overcome the negative influence of the high thermal gradient in the laser. The printing process does not require any special process control or other processing, and the printed titanium-copper alloy sample has a completely equiaxed fine-grained structure. Compared with conventional alloys under similar processing conditions, they also show excellent mechanical properties, such as high yield strength and uniform elongation. This is due to the use of high cooling rates and multiple thermal cycles to form super alloys. Fine eutectoid microstructure.

On December 5, 2019, Antarctic Bear learned that related research results were recently published in "Natrue" magazine with the title "Additive manufacturing of ultrafine-grained high-strength titanium alloys". Material manufacturing).

As mentioned in the text, the Ti-Cu alloy produced by the MAM process has completely fine equiaxed primary grains and eutectoid flakes, and has excellent mechanical properties. Experiments have shown that tunable microstructures can be realized on multiple microstructure length scales through MAM. The proposed new alloy design strategy focuses on synergistically controlling the thermodynamics of alloying elements and the solidification conditions of MAM. The authors also hope that their alloy design concepts can be applied to other alloy systems, and develop more high-performance engineering alloys for MAM in the future.

Rohy mankany amin'ity lahatsoratra ity : 3D vita pirinty vita pirinty titanium alloy dia mivoaka

Fanambarana fanontana indray: Raha tsy misy toromarika manokana, ny lahatsoratra rehetra ato amin'ity tranokala ity dia tany am-boalohany. Tondroy azafady ny loharano fanontana indray:https://www.cncmachiningptj.com

PTJ® dia manome isan-karazany Custom Precision cnc machining Shina services.ISO 9001:2015 & AS-9100 voamarina.

PTJ® dia manome isan-karazany Custom Precision cnc machining Shina services.ISO 9001:2015 & AS-9100 voamarina.

Fivarotana milina manampahaizana manokana amin'ny serivisy fanamboarana ho an'ny indostrian'ny fanorenana sy ny fitaterana. Ny fahaiza-manao dia ahitana plasma sy oxy-solika fanapahana, Masinina namboarina, MIG ary Custom Aluminium Cnc Precision Milling Welding Jig Fixture, fanaovana horonana, fivoriam-be, Lathe machining Stainless vy cnc milina hazo, manety, ary Serivisy CNC Swiss Machining. Ny fitaovana karakaraina dia ahitana karbaona sy Passivation Stainless Steel Machining Cover Plate Parts.

Lazao anay kely momba ny teti-bolan'ny tetikasanao sy ny fotoana andrasana amin'ny fandefasana. Hanao tetika miaraka aminao izahay mba hanomezana serivisy mahomby indrindra hanampiana anao hahatratra ny tanjonao, azonao atao ny mifandray aminay mivantana ( sales@pintejin.com ).

- Machining Axis 5

- Cnc fikosoham-bary

- Cnc Mihodina

- Masinina momba ny milina

- Fandaharana Machining

- Fitsaboana ambonin'ny tany

- Fanamboarana metaly

- Machining plastika

- Bobongolo metallurgy vovoka

- Fahafatesana

- Gallery Gallery

- Auto Metal Parts

- Parts Parts

- Heatsink LED

- Fitaovana fananganana

- Fizarana finday

- Fizarana fitsaboana

- Fitaovana elektronika

- Masinina namboarina

- Parts Parts

- Machining Aluminium

- Machining titanium

- Stainless vy machining

- Machining varahina

- Machining varahina

- Machining Super Alloy

- Peink Machining

- Machining UHMW

- Unilate Machining

- PA6 Masinina

- Machining PPS

- Teflon machining

- Fametahana Inconel

- Fitaovana milina vy

- Fitaovana bebe kokoa